The smart Trick of Bayside Laser That Nobody is Discussing

Table of ContentsSome Ideas on Bayside Laser You Should Know3 Easy Facts About Bayside Laser DescribedBayside Laser Things To Know Before You BuyNot known Facts About Bayside LaserNot known Details About Bayside Laser Getting The Bayside Laser To Work

Traveling optic machines need to use some technique to consider the altering beam of light size from the near area (near the resonator) cutting to the far area (far from the resonator) cutting. Typical approaches for managing this consist of collimation, adaptive optics, or making use of a constant beam of light size axis.

The power usage as well as efficiency of any kind of specific laser will certainly vary relying on output power and also operating criteria. This will depend upon the kind of laser and also just how well the laser is matched to the work at hand. The amount of laser reducing power required, referred to as warmth input, for a particular task relies on the product type, thickness, procedure (reactive/inert) made use of, and preferred reducing price.

Not known Factual Statements About Bayside Laser

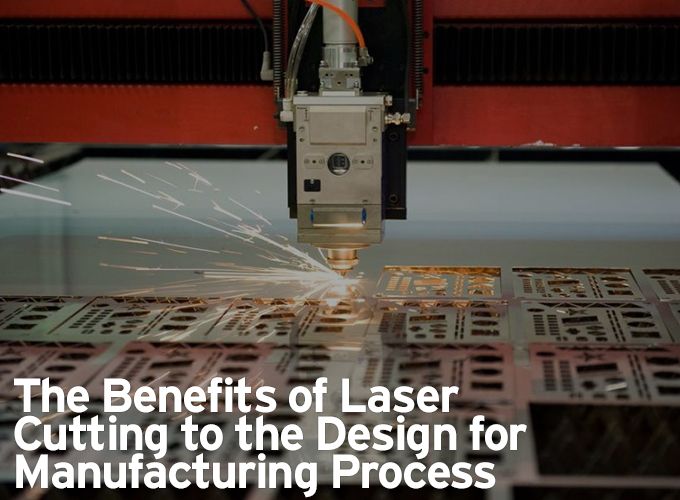

Utilizing computerised systems permits accurate as well as complicated shapes that would have been impossible with conventional cutting (laser cutting signage). The individual can quickly manage the cut's depth by readjusting the laser light beam's power and also emphasis. Laser cutting is normal in metal, wood, plastics as well as textiles. Yet it also has applications for engraving, engraving and also marking.

Whether you're searching for a new or upgrading your procedures, laser cutting has broad applications, especially in manufacturing. That claimed, right here are four advantages of laser cutting: Laser reducing is among the most innovative, specific as well as precise methods for cutting products. It can supply a level of information and also accuracy that hand tools can never ever get to.

The Definitive Guide for Bayside Laser

The possibility for laser cutting appears nearly unlimited as it supplies services premium standard results in a fraction of the moment. Laser-cutting technology is flexible and also compatible with numerous materials, varying from wood as well as natural leather to more difficult-to-cut steels. For these harder-to-cut materials, laser cutters produce perfect accuracy cuts that are not available with standard cutting tools.

Laser-cutting equipments are as simple as the majority of devices goes. Still, here are four pointers to help obtain the most out of your procedure: With laser cutting, selecting the ideal material for the job is extremely important. Depending upon the desired application, different products may be better than others depending on variables such as durability as well as safety and security.

The Single Strategy To Use For Bayside Laser

Obviously, laser cutting is a lot faster than the typical approach of reducing steel, however is it faster than other modern strategies? Laser reducing beats thermal reducing techniques such as plasma or flame in speed when cutting metal of up to 10mm thick.

For those that require to cut whole lots of different forms, laser cutting is most definitely one of the most attractive steel cutting alternative. With this technique of reducing metal, you do not require to alter devices to make various cuts as the exact very same setup will certainly execute numerous cutting work as long as the thickness continues to be the exact same.

Throughout the laser cutting procedure, the beam made use of does not actually require to touch the material that is being reduced, resulting in much less risk of damages. This means that you will not require to incur expensive repair work or postponed completion times as you may with various other methods of reducing steel - laser cutting signage.

Some Ideas on Bayside Laser You Should Know

Laser cutting requires less power than various other approaches, making use of usually 10k, W of power contrasted to 50k, W for various other reducing processes. Of program, the safety and security of your staff members is always at the forefront of your mind and laser cutting supplies among the most safe means of reducing metal.

That precise factor produces an incredibly high intensity that can reduce via the material. Compared to typical reducing methods, laser reducing deals several advantages.

Unlike many manufacturing equipments, laser cutters commonly do not need you to switch out various tools for whatever cut you want. Laser cuttings use extreme accuracy contrasted to other traditional reducing methods.

Indicators on Bayside Laser You Should Know

Depending upon exactly how a laser cutter is established up, you're frequently mosting likely to observe perhaps a tiny burr on a part. Normally, it's not essential to remove the burr, however it relies on the product, its thickness and also other elements. Oh yes, this is among the ideal components of using a laser cutter; adaptability.

No work is also made complex for the laser cutter. A very narrow section of material is quickly navigated by the high-powered laser as well as is really hardly ever warped or distorted. Projects are not just limited to sheet metal with a laser cutter. Lasers have the ability to cut stainless steel, aluminum, copper, as well as brass.